calcined petroleum coke

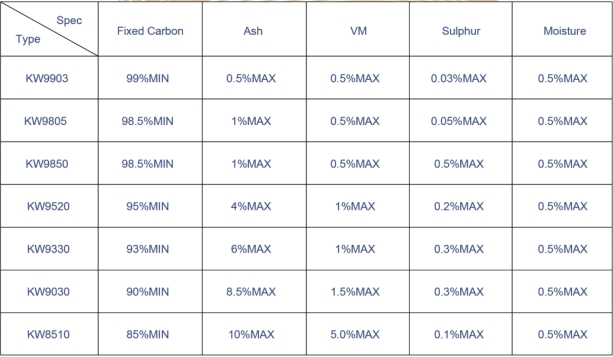

Calcined Petroleum Coke (CPC) is widely used as carbon raiser (recarburizer). Our CPC is of high carbon content, low Sulphur and of high quality-price ratio. We supply tailored particle size distributions according to customer requirements. It also can be used as Friction material for brake pads manufacturers and foundry coating additives.

Our carburizer includes artificial graphite, sintered petroleum coke, sintered anthracite, etc.

The company can customize products of different granularities according to customer needs.

Introduction to Kimwan Special Carbon Recarburizer

In the demanding landscape of metallurgical and foundry industries, Calcined Petroleum Coke serves as the foundational material for Kimwan Special Carbon’s premium recarburizers. Engineered to excel under extreme operational conditions, these products are synonymous with purity, efficiency, and reliability. By leveraging advanced processing techniques, Kimwan transforms Calcined Petroleum Coke into high-performance recarburizers that meet the rigorous standards of modern metal production.

Kimwan’s recarburizers are distinguished by their exceptional carbon content, which ensures optimal carbon recovery in molten iron and steel. The product exhibits remarkably low levels of sulfur and other impurities, thereby minimizing the risk of detrimental element introduction into the metal matrix. This inherent purity supports superior mechanical properties in finished castings, including enhanced hardness, improved tensile strength, and refined microstructural integrity. The recarburizer demonstrates excellent solubility characteristics, facilitating rapid and uniform absorption into metal baths while reducing processing time and energy consumption.

The versatility of Kimwan’s recarburizer products allows it to perform exceptionally across diverse applications, from ductile iron and gray iron foundries to specialty steel manufacturing. Its consistent composition ensures predictable outcomes, enabling manufacturers to reduce reliance on primary raw materials like pig iron and increase scrap utilization without compromising quality. Moreover, the product’s stability at high temperatures contributes to prolonged furnace lining life and reduced slag formation, indirectly lowering maintenance costs and operational disruptions.

Environmental and economic benefits are integral to Kimwan’s value proposition. The recarburizer supports sustainable manufacturing by enabling efficient resource use and reducing waste generation. Its high absorption rate translates into less material usage per ton of metal produced, aligning with both cost-efficiency and eco-conscious production goals.

As a trusted partner in advanced metalworking, Kimwan Special Carbon prioritizes rigorous quality control and tailored solutions. Each batch of recarburizer undergoes meticulous testing to guarantee performance consistency, ensuring that every delivery meets the precise requirements of clients in sectors such as automotive, machinery, and heavy equipment manufacturing.

Ultimately, Kimwan’s commitment to innovation and excellence is embodied in its recarburizer products, which empower industries to achieve new benchmarks in quality and productivity.