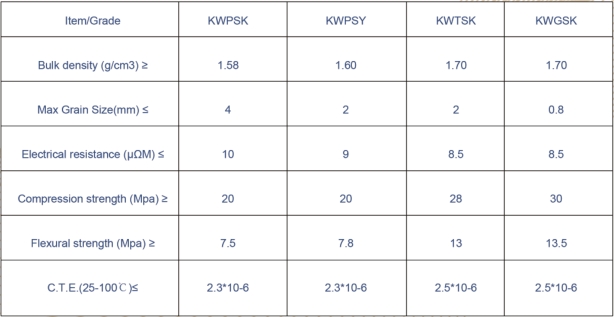

Medium grain Graphite

Medium grain Graphite produced by our company is divided into three types: maximum particle sizes of 0.8mm, 2mm, and 4mm. The performance index of the products has reached the international advanced level. With suitable resistivity and uniform structure, excellent chemical resistance, excellent oxidation resistance, and high-temperature stability, it can adapt to various harsh high-temperature environments and maintain the required mechanical strength in this environment. It can be used in below industries: molds, chemical industry, metallurgy, sewage treatment, solar industry, vacuum oven, and treatment field.

Features: Suitable resistivity and uniform structure,

Excellent chemical resistance, excellent oxidation resistance

High-temperature stability

Introduction to Kimwan Purified Graphite Electrode: Excellence in High-Temperature Industrial Applications

In the realm of advanced industrial materials, Purified Graphite Electrode stands as a critical component for high-temperature processes requiring unparalleled purity and performance. Kimwan Special Carbon leverages decades of expertise in carbon technology to produce Purified Graphite Electrode products that excel in extreme environments, offering a unique combination of thermal, electrical, and mechanical properties tailored for precision-driven industries such as metallurgy, semiconductor manufacturing, and renewable energy.

Kimwan’s Purified Graphite Electrode is renowned for its exceptional electrical conductivity, enabling efficient energy transfer in applications like electric arc furnaces for steelmaking and non-ferrous metal smelting. The low electrical resistance ensures minimal energy loss, contributing to significant operational cost savings and enhanced process efficiency. Its superior thermal shock resistance allows it to withstand rapid temperature fluctuations without structural compromise, while its high thermal stability maintains dimensional integrity under prolonged high-temperature exposure.

The mechanical robustness of these electrodes is another hallmark. The electrodes exhibit high strength and durability, resisting wear, abrasion, and mechanical stress in demanding industrial settings. This durability translates to extended service life and reduced downtime for replacements.

Chemically, Kimwan’s Purified Graphite Electrode demonstrates outstanding inertness. With ultra-low impurity levels and high purity achieved through meticulous purification processes, it resists corrosion from acids, alkalis, and oxidizing agents, ensuring compatibility with sensitive processes like semiconductor fabrication and high-purity metal melting. The low ash content prevents contamination of workpieces, critical in applications requiring ultraclean conditions.

The versatility of Kimwan’s Purified Graphite Electrode extends across diverse sectors. In electronics and semiconductor industries, it enables precise processing of materials like silicon wafers. Additionally, it supports renewable energy technologies, including solar silicon growth and lithium-ion battery production, where reliability and performance are non-negotiable.

Kimwan’s commitment to quality is evident in every stage of production, from raw material selection to precision machining. Each electrode undergoes rigorous testing to verify properties such as thermal shock tolerance, oxidation resistance, and structural consistency, ensuring compliance with international standards.

Choosing Kimwan’s Purified Graphite Electrode means investing in a solution that harmonizes performance, longevity, and sustainability. By reducing energy consumption, minimizing downtime, and enhancing product quality, it empowers industries to achieve new benchmarks in operational excellence. As a trusted partner in advanced material solutions, Kimwan continues to innovate, pushing the boundaries of what Purified Graphite Electrode can achieve in the world’s most challenging industrial landscapes.

Graphite crystallizer Chinese Manufacturer with high reputation